Why Corrosion Becomes a Major Issue

Corrosion often develops slowly, but once coating systems begin to fail, structural deterioration accelerates. Traditional access methods increase project cost, delay essential repairs and make it difficult to treat all areas effectively.

As protective layers break down, assets become vulnerable to moisture, chemical exposure and long-term structural risk.

Common Challenges:

- Coatings failing early due to poor preparation

- High access costs delaying essential maintenance

- Limited reach into tight or elevated areas

- Increased repair costs as corrosion spreads

- Deterioration affecting asset value and safety

Industrial Coating and Corrosion Protection Services

We deliver reliable corrosion protection and specialised coating solutions that extend asset life, improve surface durability and reduce long-term maintenance. Our access methods ensure safe, efficient work across complex structures with minimal disruption to your site.

Advanced Protective Coating Systems

We apply high-performance protective coating systems that safeguard steel, concrete and exposed surfaces from corrosion, moisture and environmental wear. Our process delivers a strong, durable finish that improves long-term performance and reduces ongoing maintenance needs.

VISCOTAQ Wrapping Systems

We install VISCOTAQ wrapping systems for pipelines, joints and critical structural elements that require reliable corrosion protection. The self-healing material forms a continuous barrier that protects against moisture, salts and environmental exposure.

Surface Preparation for Coating Application

We complete thorough surface preparation including cleaning, treatment and profiling to ensure coatings bond correctly. Proper preparation prevents premature failure, improves coating durability and supports long-term protection across industrial and commercial structures.

Industrial Coating Application

We apply specialised industrial coatings designed to protect assets in demanding environments. Our controlled access methods allow precise application on any elevation including hard-to-reach areas, ensuring consistent coverage and long-lasting protection.

Asset Integrity Protection

We assess vulnerable areas and apply targeted protection solutions that strengthen structural components. This service helps prevent deterioration, extend asset life and maintain the safety and reliability of commercial and industrial buildings and infrastructure.

Long-Term Corrosion Control

We provide corrosion control systems that minimise deterioration and protect assets over time. By combining advanced coatings, proven materials and ongoing maintenance strategies, we help reduce repair costs and maintain long-term asset value.

Our approach protects critical assets from corrosion, reduces future repair costs and ensures your structures continue performing safely and efficiently over time.

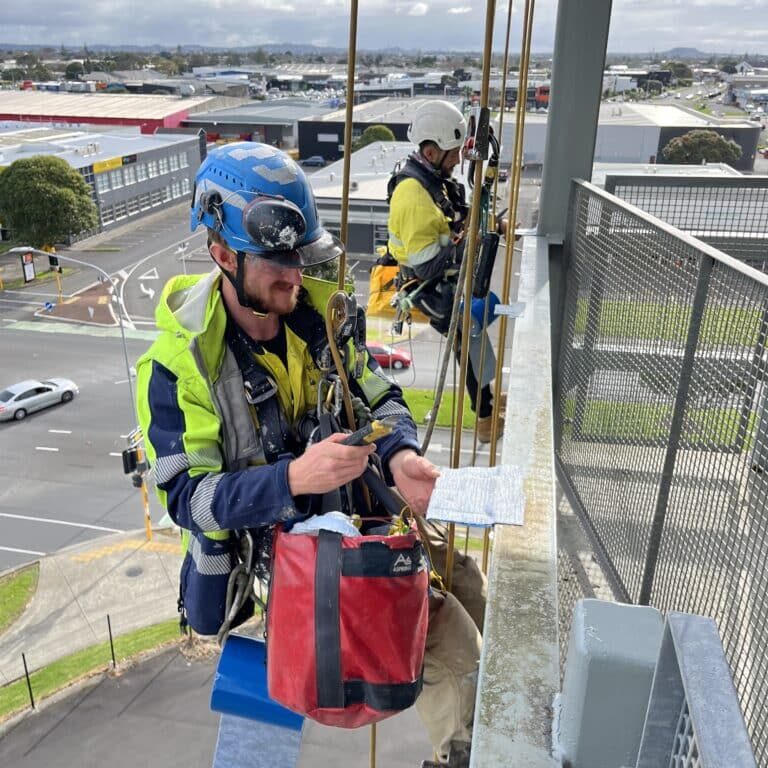

Why Rope Access Works for Coating and Corrosion Projects

Coating and corrosion work demands precision, full surface reach and controlled access. Rope access allows us to complete preparation and application safely and efficiently on difficult structures without heavy machinery or intrusive access systems. This provides consistent results and reduces project disruption.

Benefits of Rope Access for Coating Work

- Lower access costs with minimal set-up

- Precise coverage on all elevations and angles

- Safe work practices followed by certified technicians

- Faster project timeframes with reduced downtime

- Cleaner sites with no large equipment on the ground

This method helps you protect critical assets sooner, avoid unnecessary delays and maintain long-term structural integrity at a lower overall cost.

Why Our Coating Solutions Stand Out

We deliver safe, precise and high-quality coating work that restores protection, strengthens structural performance and extends the life of your assets with minimal disruption to your site. Our team brings specialised experience in coating application, corrosion control and industrial surface treatment.

We assess each structure carefully and recommend the most effective coating system to ensure long-term protection and reliable performance.

What Sets Us Apart

- Trained and certified industrial coating specialists

- Detailed preparation and precise application

- Reliable communication and clear project reporting

- Efficient access methods that reduce cost, set-up time and delays

RECENT PROJECTS

Corrosion Protection with Denso VISCOTAQ Across Multiple Project Sites

We apply Denso VISCOTAQ corrosion protection systems across a wide range of industrial and commercial structures where long-term durability is critical. Many of these assets present challenging access conditions, making traditional methods slow, costly and disruptive to ongoing operations.

Through rope access, our technicians complete inspection, surface preparation and application efficiently across elevated, confined and complex structural elements. VISCOTAQ’s viscoelastic properties allow it to bond immediately to the substrate, forming a continuous, self-healing barrier that blocks moisture, oxygen and chemical exposure. We also provide clear reporting so asset owners can verify progress and confirm the quality of completed work.

Across multiple projects, this combination has delivered durable, maintenance-free protection without blasting, priming or heavy machinery. Rope access minimises set-up time, reduces site disruption and provides a cost-effective way to safeguard critical infrastructure with reliable, long-term corrosion control.

Trusted for Industrial Coating and Corrosion Protection

Clients value our safe methods, consistent workmanship and ability to complete coating projects efficiently with minimal impact on site operations. Our team is recognised for reliable service and high-quality results across commercial and industrial sites.

Corrosion Protection FAQs

Visible rust, peeling coatings, surface staining or discolouration usually indicate coating failure. A site assessment will confirm the level of deterioration and the best protective approach.

We use high-performance industrial coatings designed for long-term protection, including anti-corrosion, waterproofing and specialised barrier systems suitable for steel, concrete and mixed materials.

Yes. Proper preparation is vital for coating performance. We manage cleaning, treatment and profiling to ensure each surface is ready for reliable adhesion.

In most cases yes. Rope access allows controlled reach into elevated, confined and complex areas that are difficult or expensive to service using scaffolding or elevated work platforms.

Longevity depends on the environment and coating type, but high-quality systems typically offer protection for many years. Regular maintenance further extends performance.

Yes. We plan work carefully to ensure minimal disruption and maintain safe access for staff and ongoing operations.

VISCOTAQ is a long-lasting, self-healing wrap designed for corrosion protection on pipelines, joints and other structural elements exposed to moisture or environmental stress.

Ready to Protect Your Assets for the Long Term?

Request a free, no-obligation quote for corrosion protection and speciality coating systems across Auckland, Hamilton and surrounding regions.

To quote faster, include your site address, the asset type (steelwork, pipework, tanks, structural elements), access height and constraints, current condition (rust, peeling, coating failure), environment (coastal, chemical, industrial), the system required (protective coatings or VISCOTAQ if known), and your timeframe. Photos and plans welcome.

We’ll respond as soon as possible with pricing and timing.

IRATA-trained • +IMPAC Prequal (Tōtika Scheme Assessed)