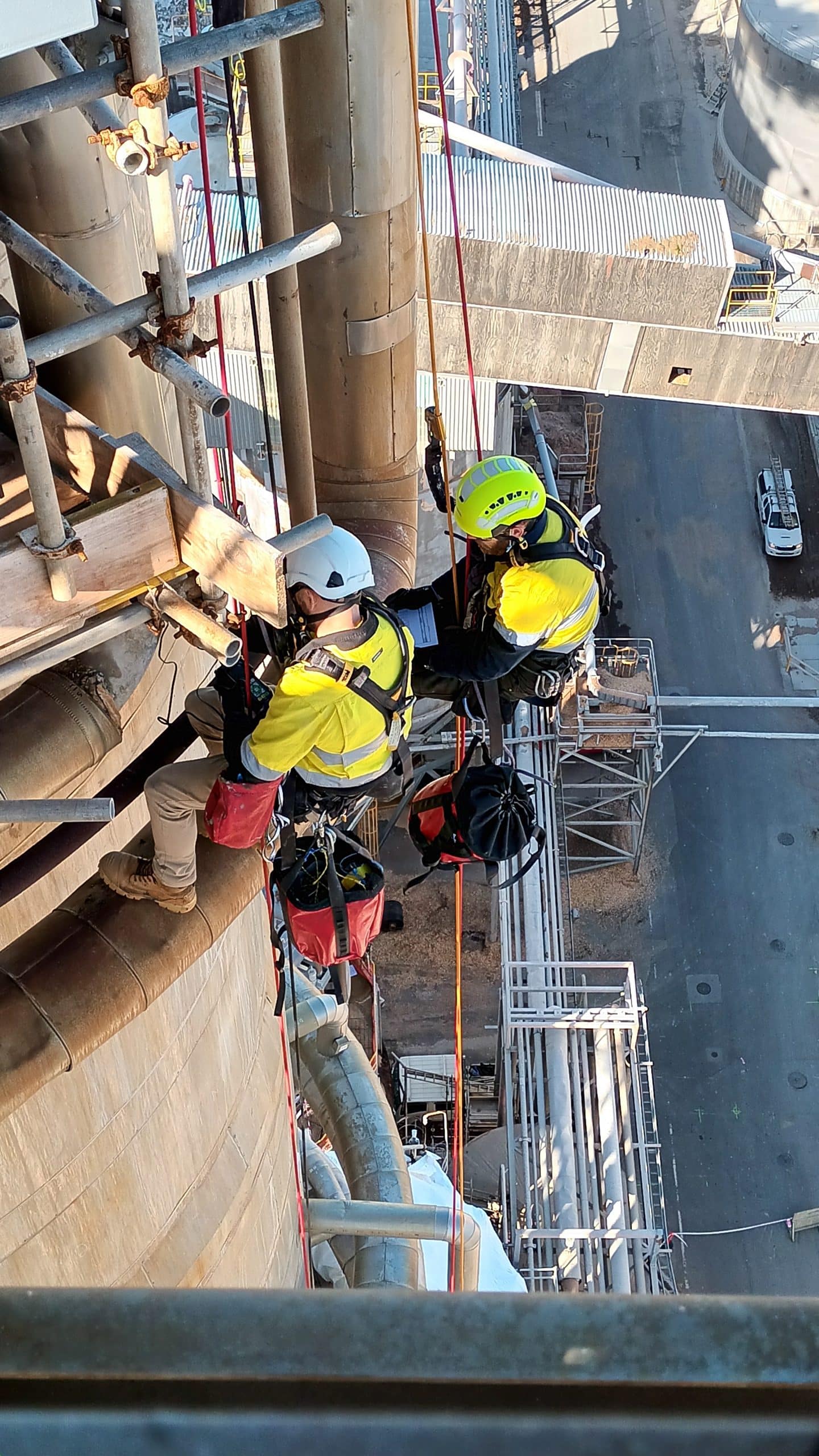

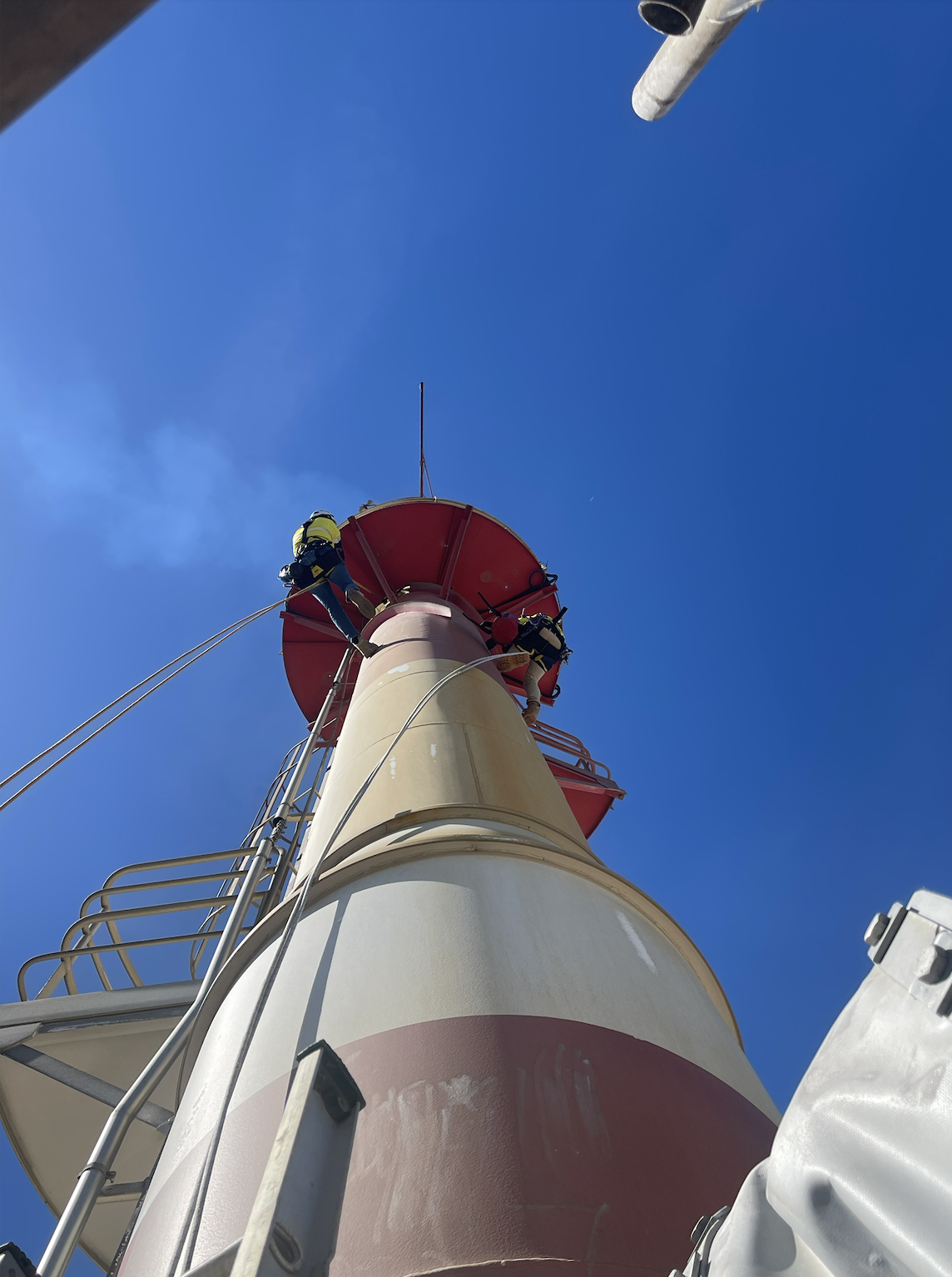

Rope Access & Non destructive testing (NDT)

Ultrasonic thickness inspection (UT) is a non-destructive testing (NDT) method used to measure material thickness and detect flaws. This technique uses high-frequency sound waves to penetrate the material.

- Probe Placement: A technician places a probe, also called a transducer, on the material's surface. This probe generates high-frequency sound waves.

- Sound Wave Transmission: The sound waves travel through the material until they hit an interface, such as the back surface or a flaw like a crack.

- Reflection of Waves: Some of the energy reflects back to the probe when the sound waves hit an interface.

- Time Measurement: The time for the sound waves to travel to the interface and back is measured.

- Thickness Calculation: The material's thickness is determined based on the sound speed in the material and the measured travel time.

Benefits of Ultrasonic Thickness Inspection (UT)

Ultrasonic thickness inspection (UT) offers several key benefits:

- Non-destructive: UT does not damage the material.

- Accurate: Provides precise thickness measurements.

- Versatile: Can be used on metals, plastics, and composites.

- Single-side Access: Can be performed from one side, ideal for hard-to-reach areas.

Combining UT with Rope Access

Combining ultrasonic thickness inspection (UT) with rope access techniques offers several advantages:

- Safety: Rope access allows technicians to reach difficult areas without scaffolding or heavy equipment.

- Efficiency: Technicians can quickly access inspection points, speeding up the process.

- Cost-effective: Reduces the need for extensive equipment and personnel, lowering costs.

- Minimal Disruption: Reduces downtime and disruptions since heavy machinery and scaffolding are not required.

Applications of UT Inspection and Rope Access

- Corrosion Management: UT detects corrosion in pipes, tanks, and structural components.

- Structural Integrity: Ensures the safety and reliability of critical infrastructure.

- Maintenance Planning: Helps in planning maintenance and repairs by identifying areas needing attention early.

Using the latest UT tools and rope access methods, Connect Access provides comprehensive inspection services. This ensures structural safety and compliance with industry standards.

Learn More

Contact Us

For more information on our UT inspection and rope access services, visit our Contact Page.